In todays extravagant subwoofer system installations we saw a need to provide a multi-functional devices to aid in giving the user real-time feedback on important measurements. The M2-V/T was developed as a tool for high performance subwoofer systems to monitor system DC voltage along with real-time temperature measurements. In 2019 we set out to design a unit that would allow for easy installation, setup, and use as well as be durable to withstand the installation environments. This setup was designed from the ground up to meet these requirements.

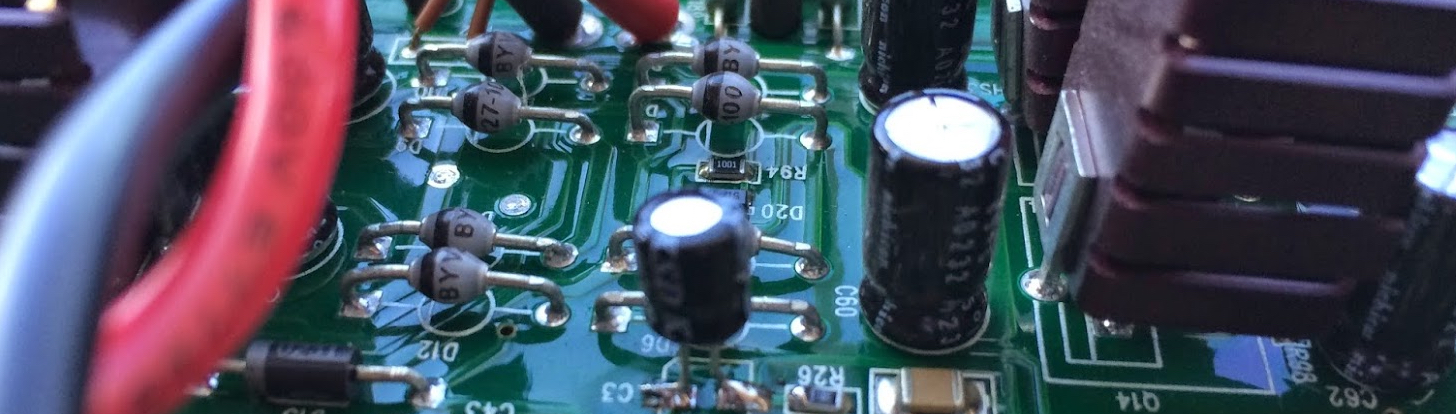

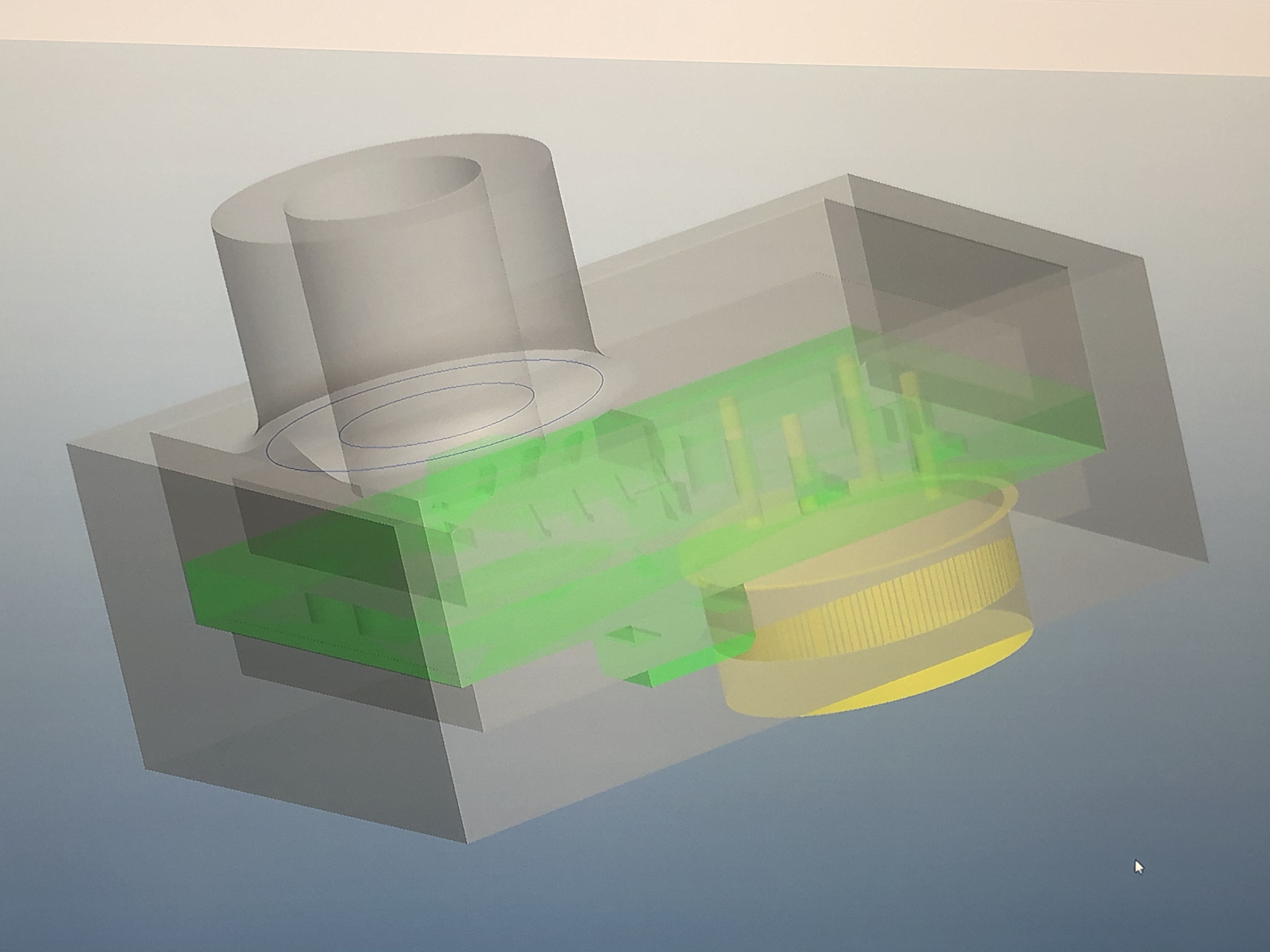

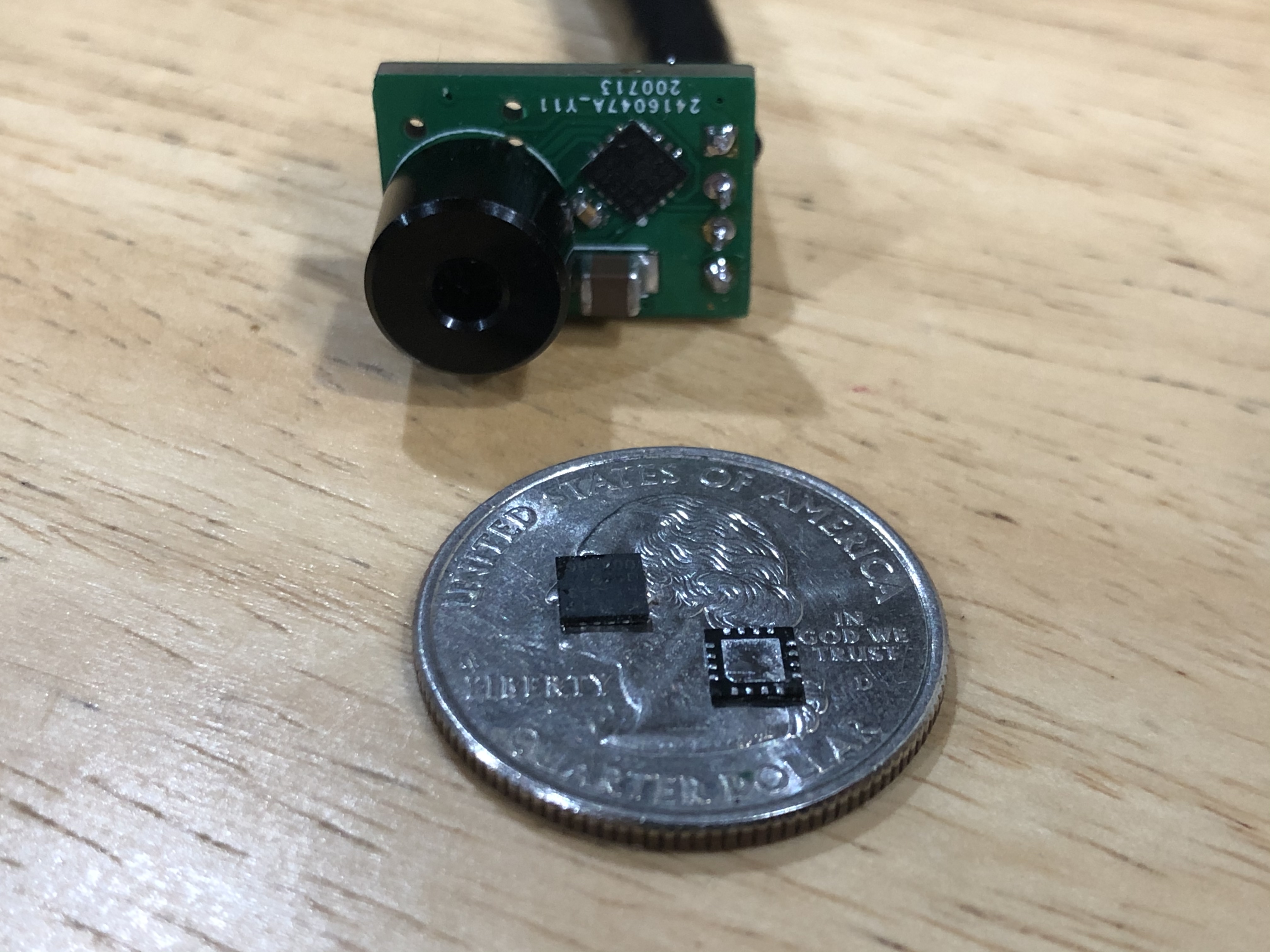

We started with laying out basic circuits and prototyping to get a basis for how the unit should operate. This quickly rolled into a full blown engineering task to miniaturize and fit all the required components into small durable packages that interconnect with off the shelf wiring to make installation and end user customization easier.

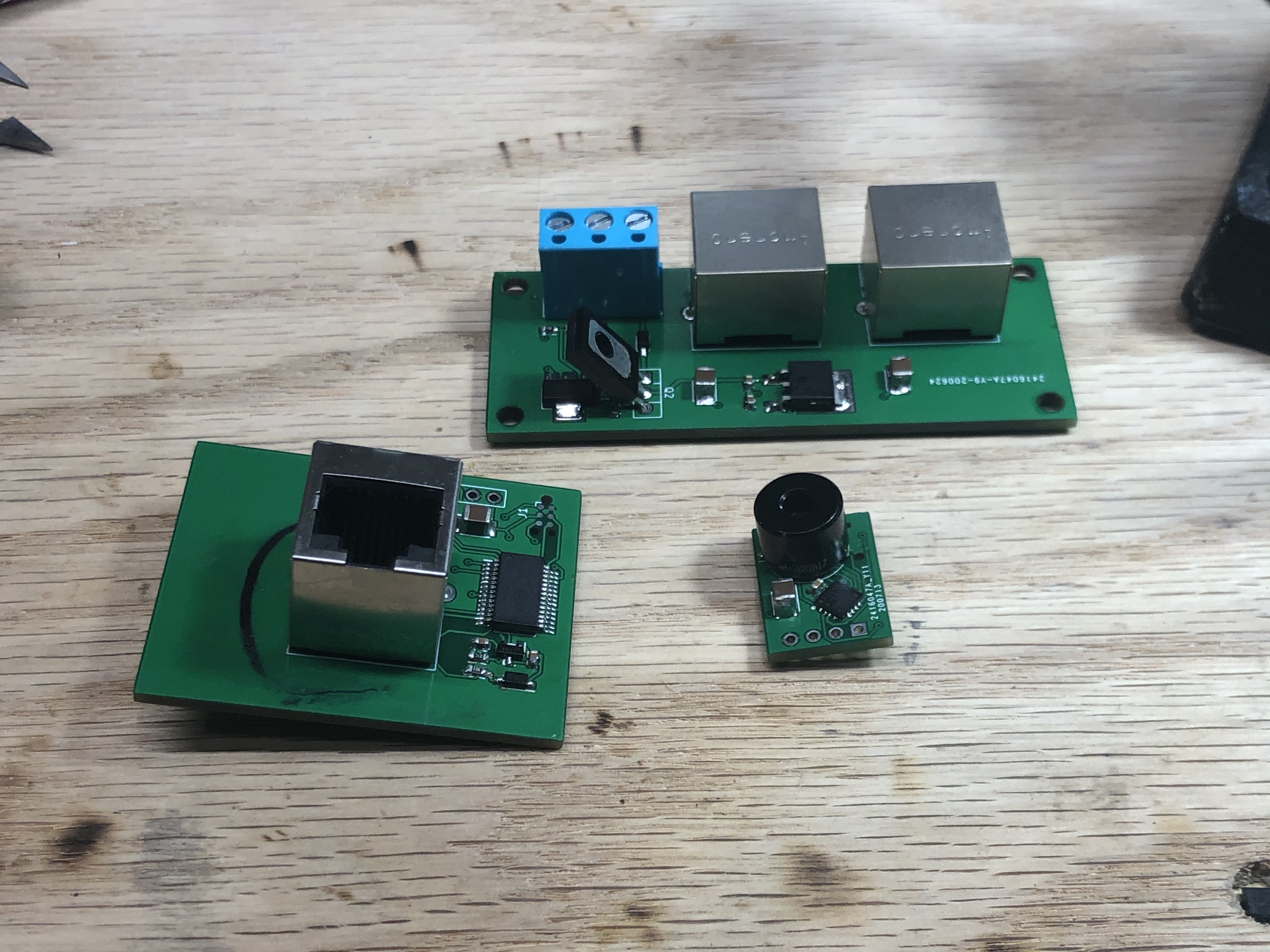

Interconnection wiring is all basic CAT5E cable as it can be purchased nearly anywhere in various lengths to easily accommodate your install if you need something out of the ordinary. The power to the unit is supplied via a 3 position terminal block (GND, 12V, and Remote) which is a very familiar configuration to many installers.

The IR sensor package was designed to provide several functions. We went with a fully enclosed package with integrated cable strain relief for durability and protection of the circuits. The IR sensor location is offset so the enclosure can be installed in several orientations to help best align the IR sensors view to the voice coil. Lastly, we use IR sensors that have a smaller field of vision than most to really help focus the readings on what matters.

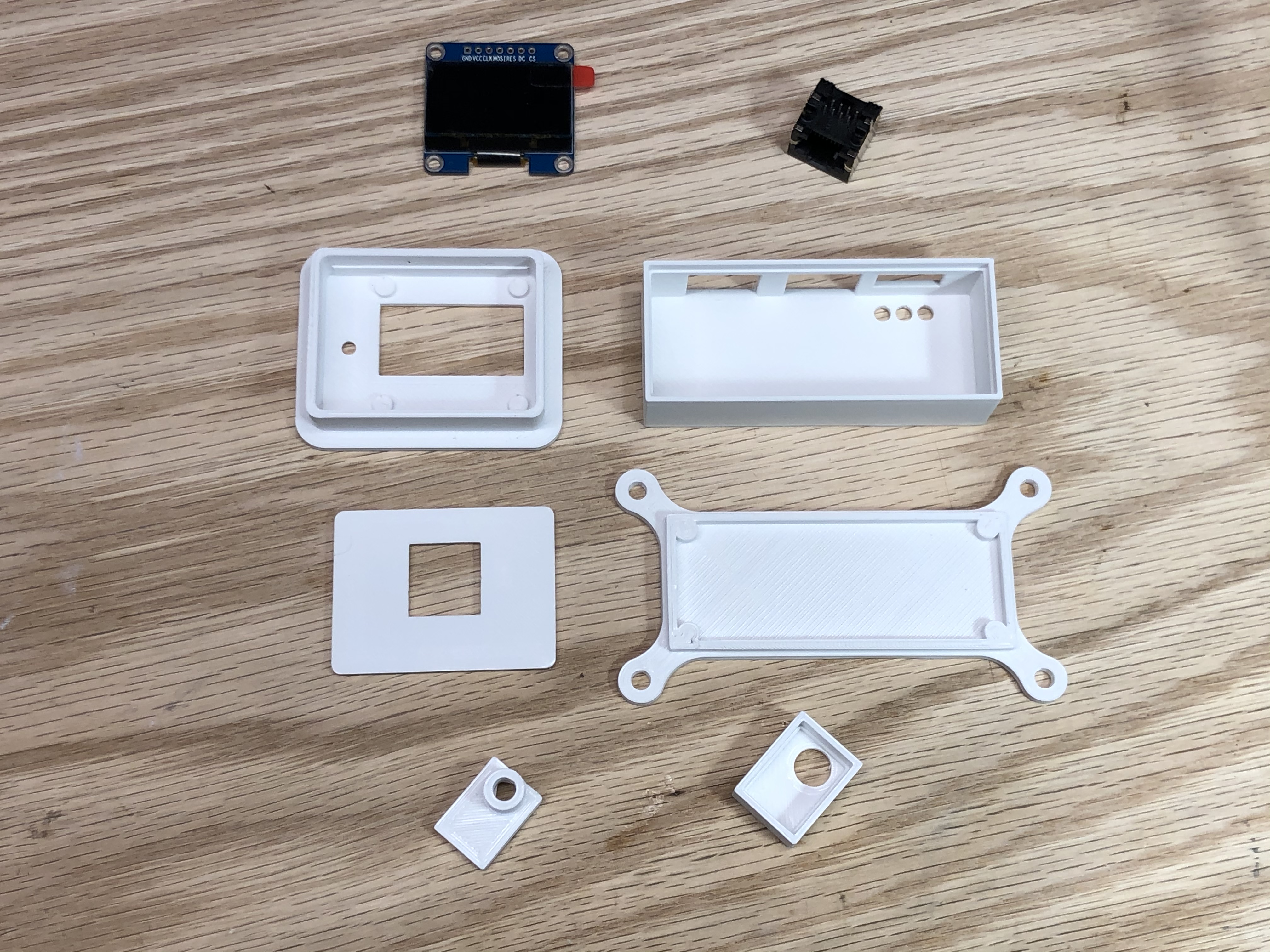

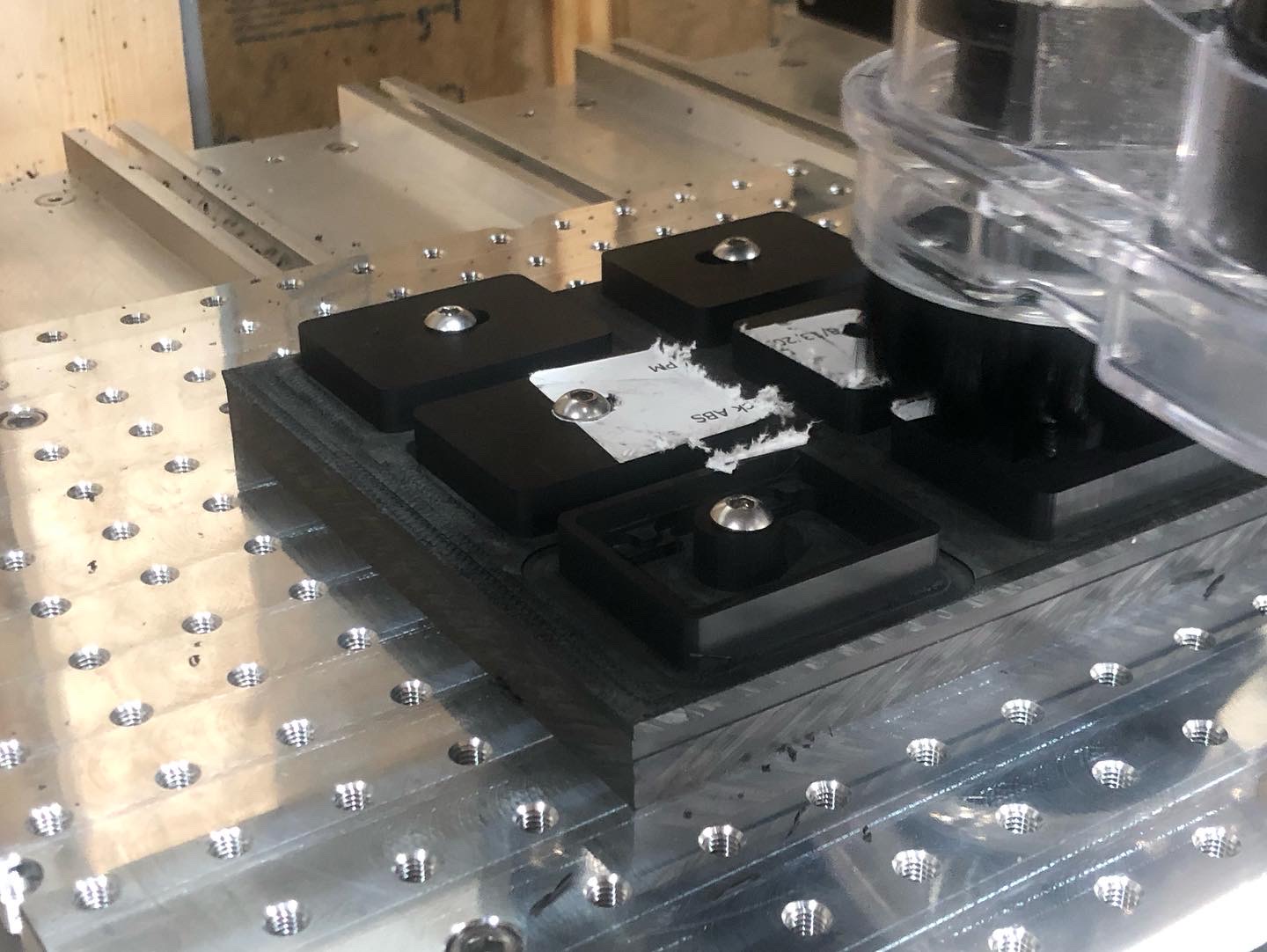

Our display housing is machined in-house from a solid block of ABS. Machining the display housing allows for a stronger more durable product that is easier to prep and finish to look cosmetically pleasing. A 3D printed part is not as strong and requires additional steps to have a similar desired surface finish.

Our sensor housing and power connection hub are still 3D printed as they are produced with thin wall features that are more difficult to attain suitable results being machined. The combination of in-house machining and printed parts results in cost savings that are passed along to make the unit more affordable.

Final version as shipped samples!

For more detailed infomation please refer to the manual here.